|

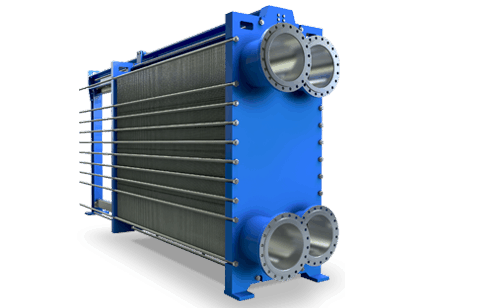

SCHMIDT® SIGMA Gasketed Plate ExchangerPlate heat exchangers use corrugated plates stacked between a fixed and movable pressure plate. As virtually all of the material is used for heat transfer, plate heat exchangers can have large amounts of effective heat transfer surface in a small footprint. It is not uncommon that a plate heat exchanger will have the same thermal capacity as a shell and tube five times larger. API Heat Transfer plate heat exchangers incorporate superior design features to ensure long-term performance and customer satisfaction. |

|

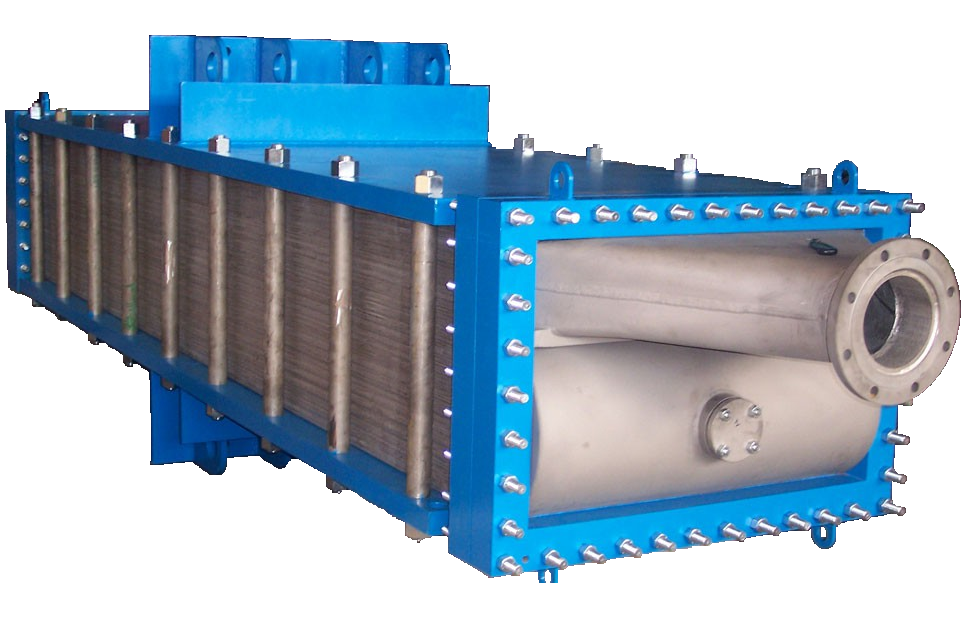

SCHMIDT® SIGMASHELL All-Welded Plate & Shell ExchangerSealless and with a heat transfer surface area up to 700 m2, API Heat Transfer SIGMASHELL laser-welded plate and shell heat exchangers are ideal for thermal treatment of liquid, vapor, and gas. SIGMASHELL is applicable in all industrial sectors, including chemical and petrochemicals, pharmaceuticals, renewable energies, bio energy, power generation, pulp and paper, steel mills, and coking plants. |

|

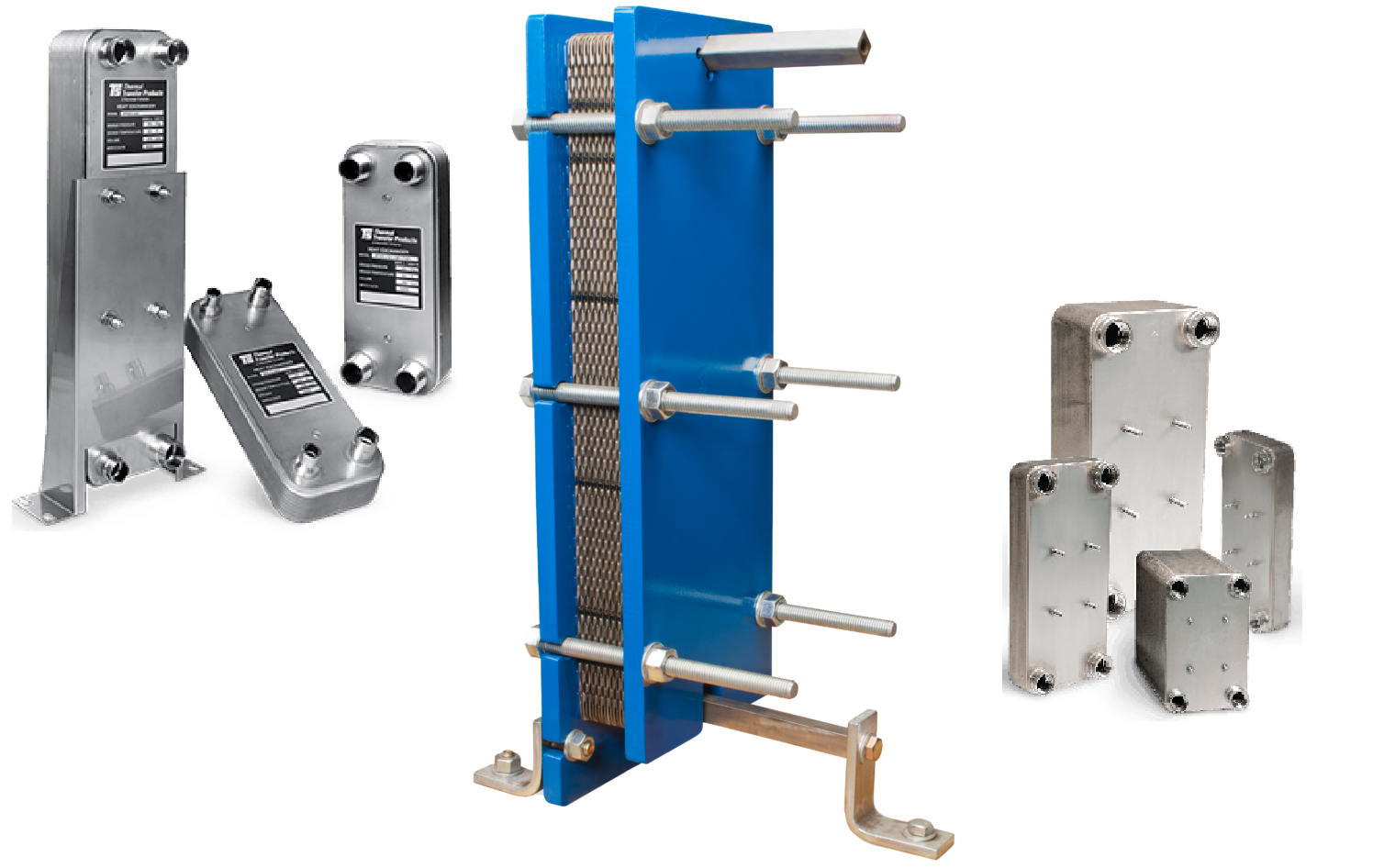

SCHMIDT® SIGMABRAZE Plate ExchangerAPI Heat Transfer SIGMABRAZE brazed plate heat exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial, process, and refrigerant applications. Built from 316 stainless steel with copper brazing materials, they provide exceptional corrosion resistance. Due to the smaller size and reduced material content, they can be the most economical heat transfer choice. |

|

SCHMIDT® SIGMAWIG All-Welded Plate ExchangerAPI Heat Transfer's line of Schmidt SIGMAWIG all-welded plate heat exchangers. Built entirely without gaskets or with an O-ring type gasket between the all-welded plate pack and frame, they provide exceptional corrosion resistance. The exchanger features corrugated plates that produce highly turbulent flow in a true counter-current direction. The result is high efficiency in a very compact design. Due to the smaller size and reduced material content, welded plate heat exchangers can be the most economical heat transfer choice. |

|

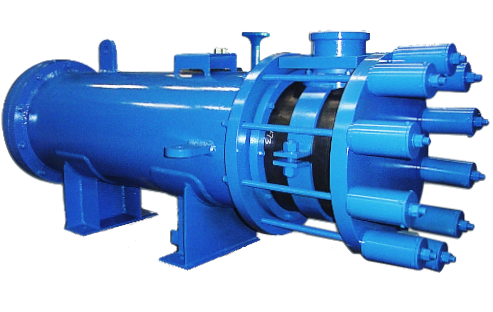

FBM ICOSS Fully Welded High Pressure Plate ExchangerThe fully welded plate HE PLATEBOX has been created from 20 years of FBM Icoss experience in the production of welded plates and high pressure vessels for the chemical field and aerospace industries. This unit can handle up 100 bar pressure or more. Easy inspection and cleaning for maintenance. |

|

SCHMIDT® SIGMADUAL Semi-Welded Plate ExchangerAPI Heat Transfer SIGMADUAL semi-welded plate heat exchangers feature plates that are welded using advanced laser welding techniques. Two plates are welded together and can be fitted with a Viton® O-Ring and/or Teflon® gasket liner. The resulting plate pack has every other plate fully serviceable, while maintaining integrity of the welded plate pair. This is especially suitable for critical fluids and gases, such as ammonia or caustic process chemicals where fluid loss is not acceptable. In the case of ammonia refrigeration, the reduced volume results in significant savings. |

|

SCHMIDT® SIGMA G-BLOC Graphite Block ExchangerAPI Heat Transfer SIGMA G-BLOC graphite block heat exchangers are ideal for use with corrosive materials, offer nearly universal corrosion resistance, and are the highest strength on the market. Made of modular, stacked graphite blocks with mounted PTFE seals between each adjoining block, the blocks are drilled in a specific pattern to optimize heat transfer through the graphite material. |

|

Pre-Engineered Plate ExchangersThermal Transfer Products offers a full line of process plate exchangers. This includes standard catalog items that are available in short lead times. A variety of materials of construction are offered along with various gasket types and plate profiles. API Heat Transfer can help you select the right product for your application. |